Stepping beyond a ‘business as usual’ mindset

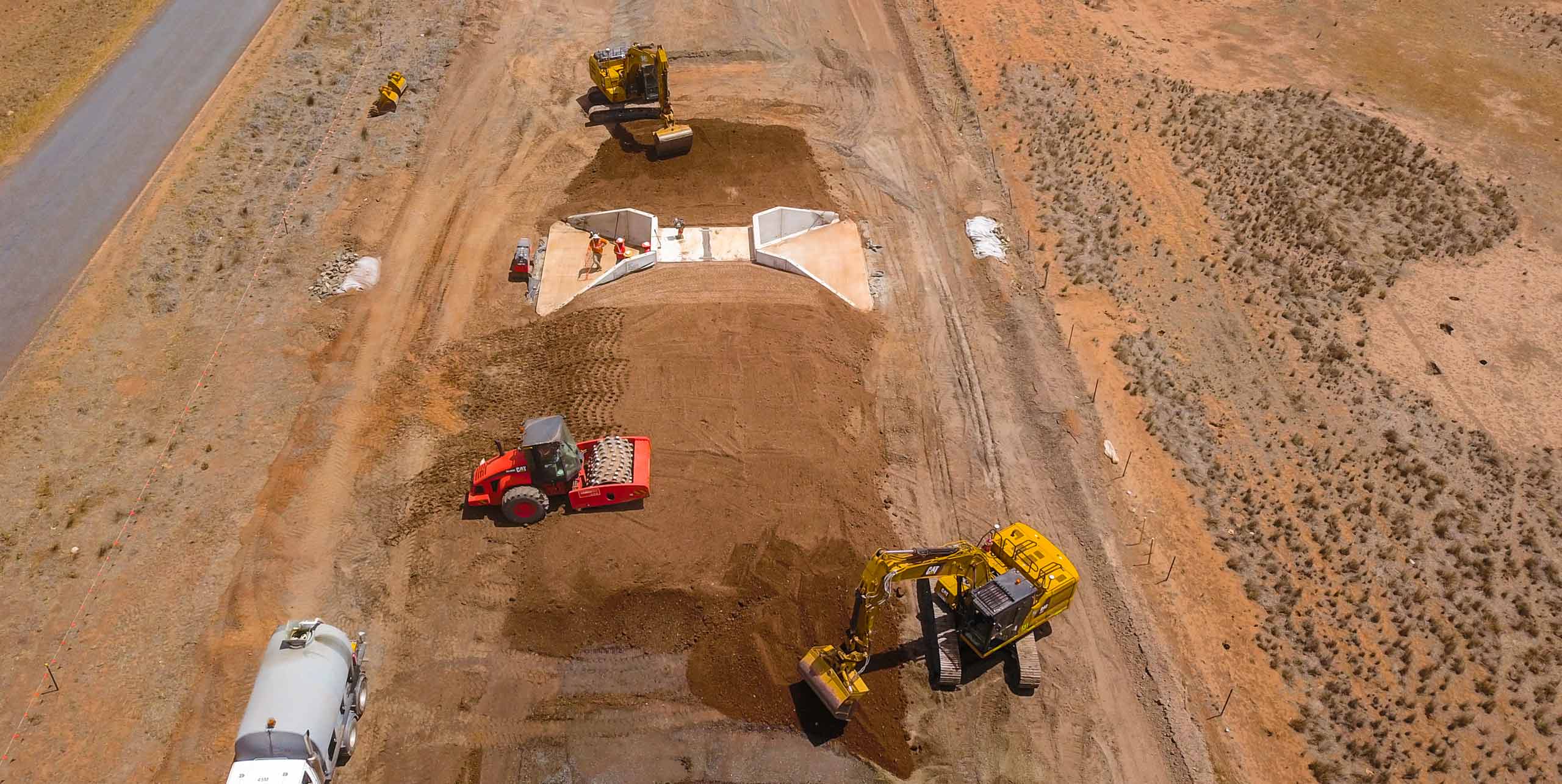

A key example of innovation in action is the development and implementation of new suite of earthworks specifications with a move from a prescriptive to performance-based approach.

Formation and bulk earthworks make up around a third of the Inland Rail’s capital cost. The previous earthworks specifications did not adequately address the varying geotechnical solutions and technical challenges along the route, including different soil types and sourcing of suitable materials.

Working with a broad range of stakeholders and subject matter experts, we identified an opportunity during the concept development phase to move to performance-based earthworks specifications. Compared to the prescriptive methods, these specifications are agile enough to provide for design optimisation and encourage new methods of construction and materials sourcing with an aim of providing geographically sensible earthworks solutions that don’t rely on importing high volumes of high-grade materials.

“Developing and implementing project specifications is a major undertaking that is rarely seen in the Australian rail industry,” says Dr Richard Kelly (Geotechnical Subject Matter Expert on the SMEC-Arup Joint Venture) “These performance-based specifications represent current industry best practice and have delivered value engineering for the program’s earthworks, whilst also presenting opportunities for advancement in engineering and design of railway earthworks throughout Australia.”

Successful implementation has driven positive outcomes on the Parkes to Narromine (P2N) project. This is 103.7km section is the first Inland Rail project be completed and was commissioned in September 2020. It is estimated that the alternative earthworks solutions supported by these specifications will save the project over $100 million in costs. They also provide a legacy to the rail operator and maintainer for use beyond the Inland Rail project.

Expertise at work

SMEC, and our JV partner Arup, are providing engineering and technical advisory to our client through specialist support across the disciplines that make up the delivery of the railway system. A full-time core team of almost 50 experienced engineers is based in our client’s Brisbane office, supported by a wider group of nearly 150 Subject Matter Experts (SMEs). This has developed a highly collaborative structure between the joint venture partners and our client, enabling a team environment in which innovation is able to be fostered and capitalised upon.

In addition to providing program-wide and project-specific advisory services, the team has also developed a range of technical strategies and documents including standard design drawings, program requirements specifications and social performance reporting framework. As the program moves forward into the next phase, the team has also undertaken optimisation reviews across several projects to ensure the client is receiving value for money solutions.

The outcomes

Improved infrastructure and an effective national freight operation will not only provide supply chain benefits but will also lift Australia’s global competitiveness whilst delivering substantial cost savings for local producers. SMEC’s engineering, geotechnical and construction capability and specialist support have played a key role in the current delivery of Inland Rail and for rail infrastructure projects and maintenance well into the future.

“It is a great opportunity to work with and lead such a talented team on a project like Inland Rail. Every day we are contributing to the future of Australia’s rail and transport network,” said Lyndsey Bannister, SMEC-Arup JV Project Manager.

Related

insights

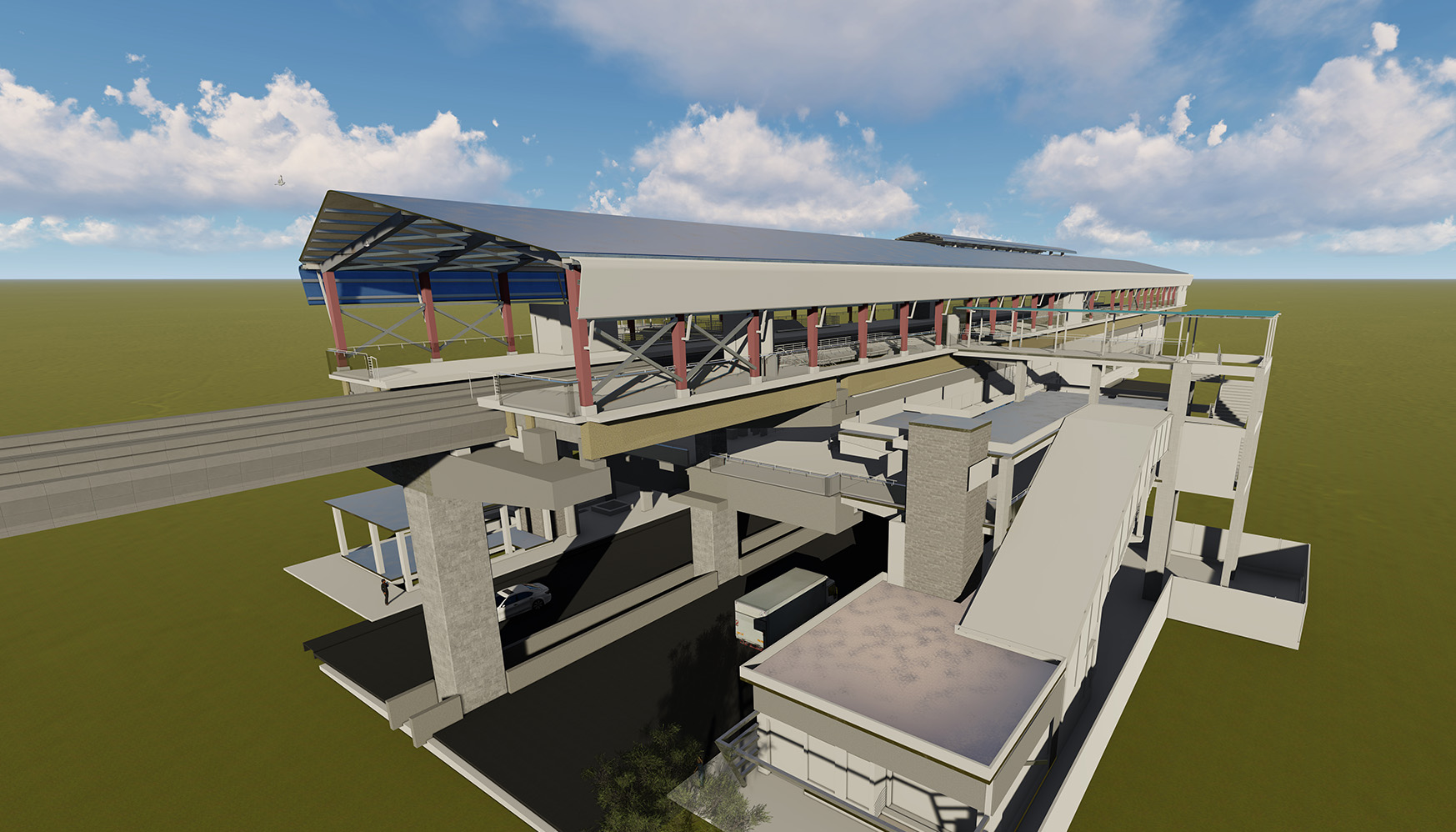

Construction commences on key section of Chennai Metro Rail’s Phase 2

Construction commences on key section of Chennai Metro Rail’s Phase 2

Our design comprises an integrated rail and road bridge with double decker stations, which will carry both highway and mass rapid transport commuters on the same pier.

Energising a nation’s capital: Canberra Light Rail

Energising a nation’s capital: Canberra Light Rail

It was an exciting Saturday in April 2019 as the Canberra Light Rail, after more than a decade in planning and construction, opened its doors to the public. It’s the first light rail system for Australia’s capital and a key element of the Australian Capital Territory (ACT)’s Government’s Canberra Plan, a strategic guide to the city’s future growth.

Dohazari to Cox's Bazar Railway project, Bangladesh reaps benefits of site safety culture

Dohazari to Cox's Bazar Railway project, Bangladesh reaps benefits of site safety culture

Health and safety should be an integral part of businesses, of all shapes, and sizes. At SMEC it is imperative that we protect the well-being of people associated with our company, whether on-site or in the office.

Strategic Insights Inform Regional Transformation

Strategic Insights Inform Regional Transformation

It is an exciting time to live in Southeast Queensland (SEQ), Australia. It’s even better if you work in planning and engineering. This is because a complex, multi-faceted City Deal proposition called TransformingSEQ was recently launched, followed by in-principle agreement at the local, state and federal levels of government to progress the SEQ City Deal proposal. City Deals are a key mechanism of the Government’s Smart Cities Plan (2016) and provide a new approach for all levels of government to work together to strategise and deliver transformative outcomes for Australian cities.