Temporary work solutions to fast-track construction

The remoteness of the project as well as the logistics of travelling from the northern side to the southern side – a three-hour drive – means that a cable way has been installed as part of the temporary works. A mono-rope cable system, equipped with a six person cabin is being used to transport people and small amounts of material from one side to the other. The cable car takes only eight minutes to traverse the gorge resulting in a significant time saving for all crew on site. The project has also been aided by an agreement between the South African National Roads Agency (SANRAL) and the Magwa Tea Estate, the biggest tea estate in the Southern Hemisphere. Magwa has provided 8ha of land for the Engineering teams accommodation camp which houses the majority of SMEC’s site staff.

Structural health monitoring system

A structural health monitoring system was installed to monitor the bridge in its permanent state. The system comprised a modular design, which could be expanded, if required. Data sensors included Static Strain Gauge, Thermistors, Stay Vibration sensors, Biaxial Accelerometers, Tilt Meters, Displacement Transducer, Anemometer as well as various weather sensors. A GPS was installed at the top of the pylon structure to monitor real-time movement and the impact of temperature gradients.

Impact

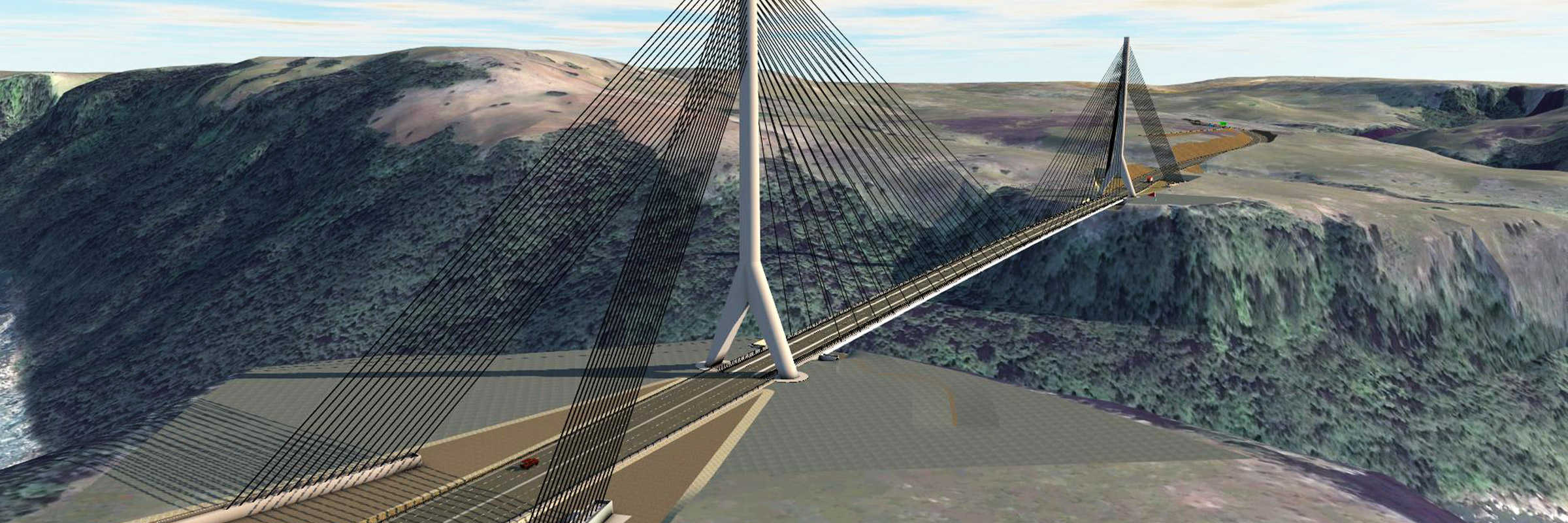

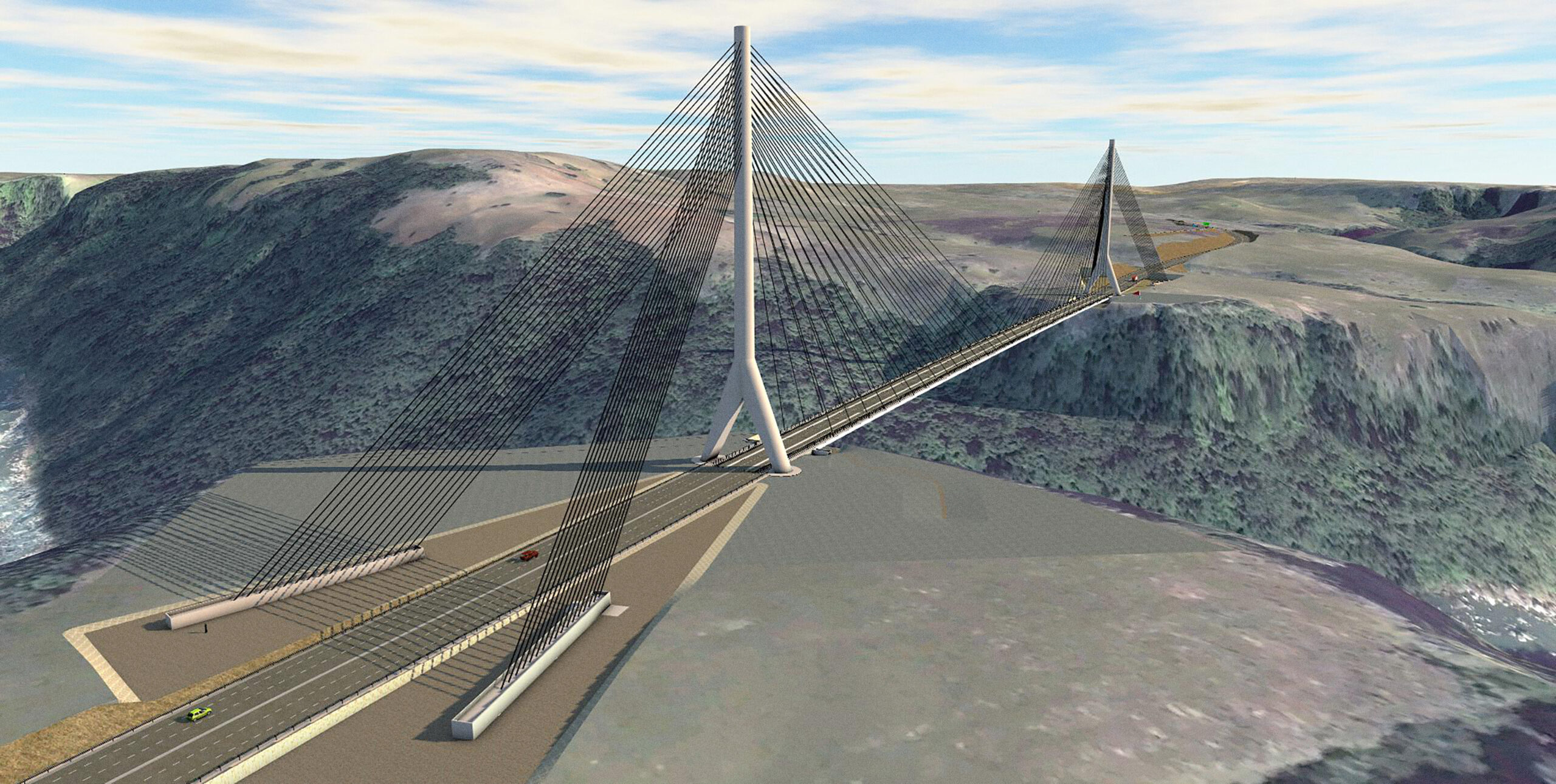

The support pylons reach heights close to 85 m and held by four anchor blocks, completed at the end of 2023. Erection of the complex deck is scheduled to start in the second quarter of 2024. Once complete, the route will be 69km and 85km shorter than the current N2 and R61 routes, respectively, and, owing to its shorter and flatter alignment, between 1.5 to three hours faster for light and heavy freight vehicles.