Since 2012, SMEC has been delivering detailed engineering and design consultancy services for the run of river project, providing unique design solutions along with reduced construction time and costs.

Fragile conditions create unique opportunity

Difficult geological and cyclical weather conditions created several technical challenges. Our aim was to optimise construction time and costs while also ensuring we minimised disturbance to the surrounding natural environment, the existing National Highway and resident communities.

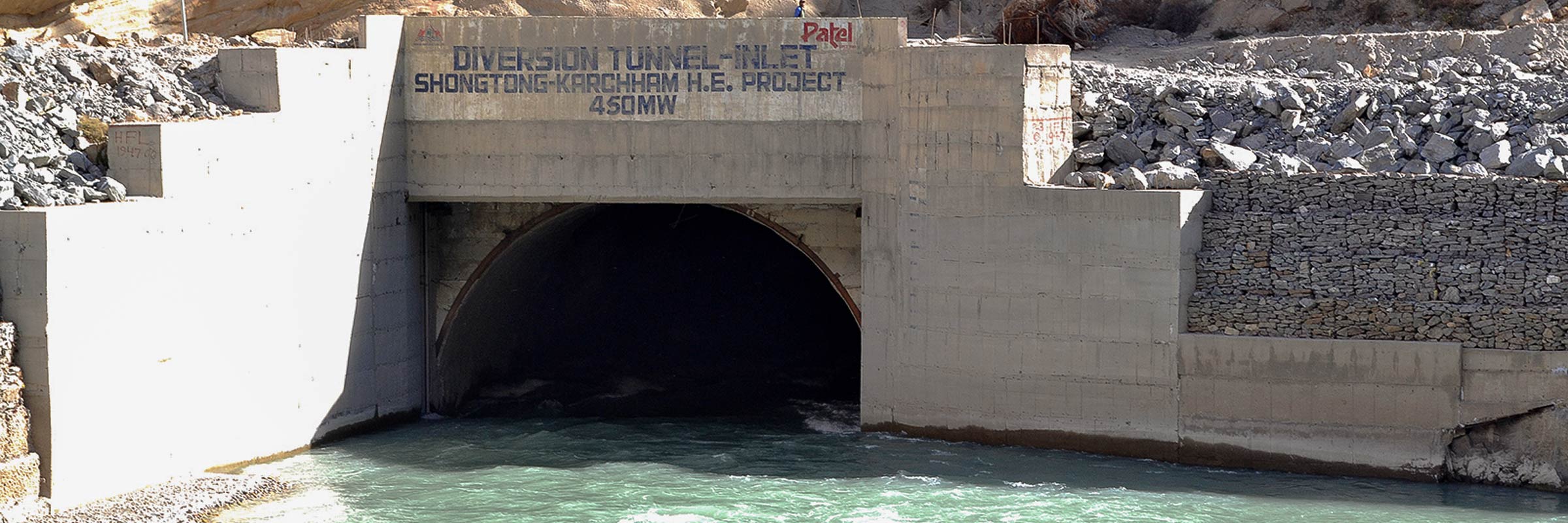

A uniquely optimised diversion tunnel design

“The project being located on the upper reaches of the Satluj River, we faced a significant issue with river diversion for barrage construction, given the fragile geological conditions on the right bank with a major township and national highway connectivity in close vicinity,” says Neeta Arora, Head of Design Centre in India.

The team developed a unique design for a Double D-shaped (14.8m x 8.5 m) diversion tunnel with a reduced length (601m compared to the original length of more than 2km) but optimised dimensions to safely carry discharges downstream of the barrage. Due to excellent rock conditions in the left bank, we proposed lining in the invert only, which would have minimal impact on energy loss but reduce construction time and cost.

The tunnel was constructed successfully and has been operating as designed for the past few years.

Building monsoon resilience into the cofferdam

It was essential to minimise the time required to reconstruct the cofferdam following every monsoon season, to increase the working period for the construction of the barrage. With monsoon season running from June to September each year, this placed some restraints on planning.

A breaching section of compacted earth fill 4m high with a 60m long crest was added to the upstream cofferdam, sandwiched between the rock fill shoulders of the 11m-high embankment dam. This minimised any re-construction work required as only the breaching section would need repair. The breaching section limited the pondage behind the upstream cofferdam and could cater for monsoon flood discharges, with an overflow section below provided with stepped energy dissipation.

Optimising barrage design within constraints

The barrage had its own geological challenges, including its location in a straight reach of the river, stabilisation of the river bank for the barrage intake, minimising disturbance on the opposite bank and proximity to the National Highway.

After ground investigations and hydraulic studies, we recommended shifting the location of the intake 50m further downstream than originally proposed, to avoid the debris zone on left bank. This also meant relocating the dam axis 60m downstream. The number of bays was reduced from six to five to address fragile river banks and minimise disturbance to the National Highway. These adaptations allowed for the safe passage of flood water and kept the intake in a stable zone.

“A team of specialists including hydrologists, hydraulic engineers, geotechnical & structural engineers and geologists brainstormed and collaborated to develop these optimised design solutions,” explains Piyush. “By leveraging multidisciplinary expertise, we were able to arrive at the most workable engineering solutions, considering serviceability, ease of construction, executional safety, technical specifications and standard codes along with best practice and optimised construction time and cost.”