Challenging boundaries of design thinking

To facilitate the extensive use of precast concrete, the team developed an integrated geotechnical and structural design, particularly focused on capturing the complex soil structure interaction (SSI).

“Conventional structural design methods often neglect the effects of SSI, which is typically associated with earthquake design,” said Eugenio Mayol, Principal Engineer – Structures at SMEC. “However, this approach was essential to the success of the precast design innovation.”

Adopting the SSI approach to determine the ground pressure for the permanent walls’ design reduced the station box wall thickness requirement, resulting in significant material savings. This also meant more sustainable outcomes through reducing material usage.

Innovating through technology

“It is well acknowledged that designing with precast concrete adds more complexity and effort in coordinating penetrations and services. Fortunately, the BIM environment offered the best, if not the easiest, solution to coordinate the multitude of interfacing services,” said Willem Van Ede, SMEC Senior Associate Engineer.

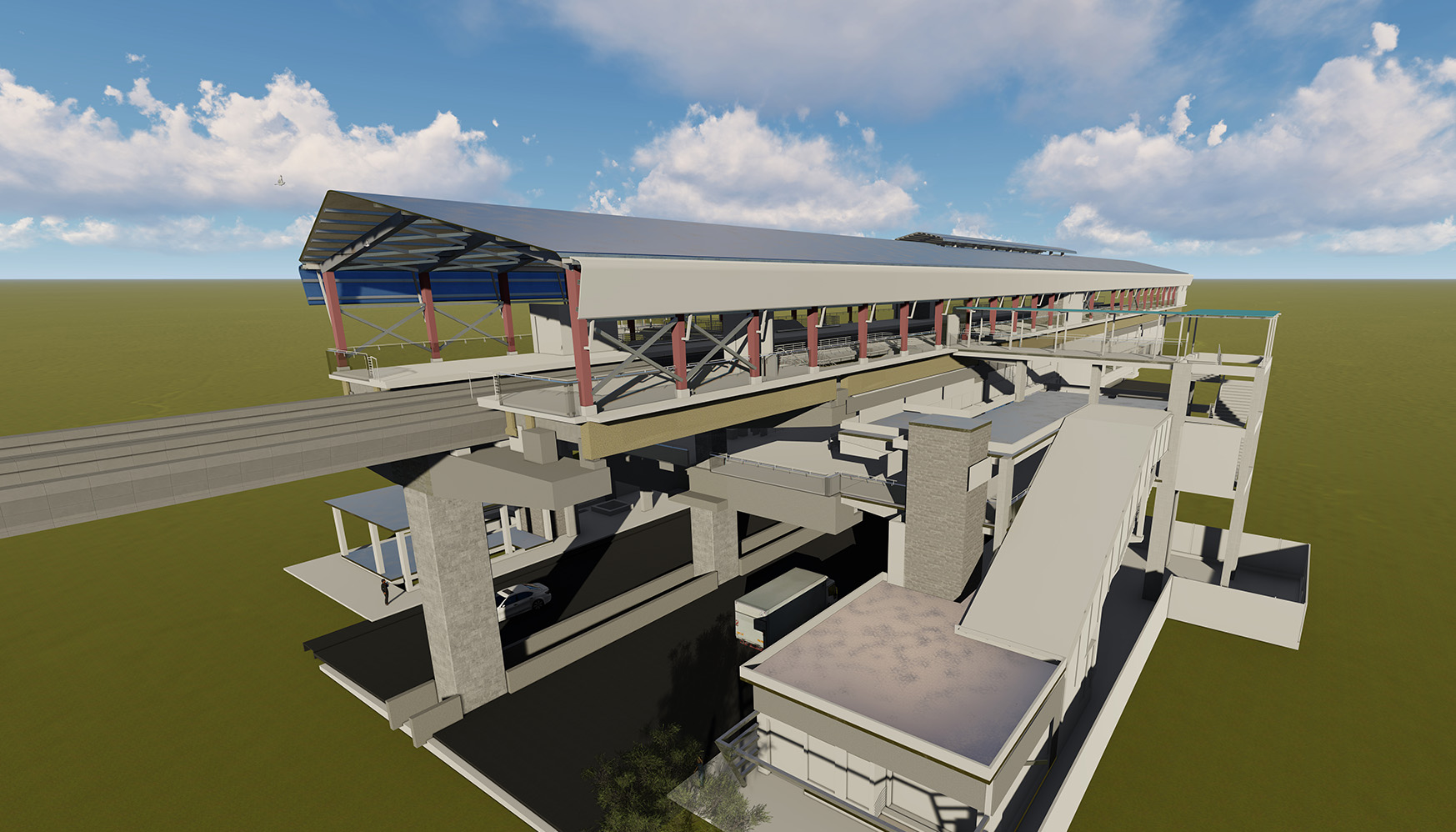

This project is a leading example in the infrastructure consulting environment for the use of Building Information Technology as the main tool of inter-discipline coordination and design. It is the first project of its size in Australia to be fully documented and coordinated in BIM.

Implementing BIM allowed the design team to deliver a system-wide, 3D working environment that enabled interdisciplinary collaboration among architects, building services, structural, civil, and rail systems working groups.

“It’s often been said that technology is only as good as its user,” commented Sav Dell’Aquila, SMEC’s Principal Project Manager. “In this case, I believe it was an optimal combination of talent with digital technology to develop a working environment that nurtured and enabled design innovations, ultimately allowing us to optimise precast construction.”

Enduring outcomes

As a result of innovation and design optimisation, more than 90% of the main structure was precast, an unprecedented achievement. The precast concrete solution meant that the design required minimal changes upon installation and could be standardised, allowing for repetition in construction methodology which led to cost and time savings.

The successful use of precast concrete construction on this project has led to the same approach being adopted on the metro station design at Crows Nest, part of the Sydney Metro City & Southwest project.

“The innovations led to overall design excellence in managing the challenges of the project and resulted in cost savings, efficiency and a sustainable outcome,” says Michael Barron, DJV Project Director. “Sharing these learning across the industry, Mott MacDonald, SMEC and KBR have published papers and presented at events so that others may benefit from these outcomes.”

Since opening, the Sydney Metro North West has carried 25 million customers on more than 155,000 services, with a customer satisfaction index of 96 per cent (as at November 2019).